Choosing the Right Industrial Fruit and Vegetable Cutting Machine for Your Operation

The right industrial fruit and vegetable cutting machine depends on the specific products you handle, the volumes you process, and the cuts you need.

Some operations focus on leafy greens that require clean, uniform slicing, while others prepare root vegetables that need dicing or chunking at scale. High-volume facilities that run continuous shifts need machines that can keep up without slowing production.

Commercial kitchens may need compact systems that fit into existing lines without full reconfiguration. Processing apples, carrots, peppers, or melons brings different cutting requirements and workflow considerations, and getting the right industrial vegetable or fruit cutter will set you up for success.

Key Features to Look for in Industrial Fruit and Vegetable Cutting Machines

Once you’ve established your product types and processing goals, it’s time to evaluate how different machines meet those demands.

Industrial vegetable cutting machines vary widely in function, build, and long-term performance. The same applies to industrial fruit cutting machines, which often require separate handling and discharge considerations. Thus, buyers must consider both the technical and practical aspects of each unit before committing to a purchase.

We suggest looking for the following features when comparing industrial fruit and vegetable cutting machines:

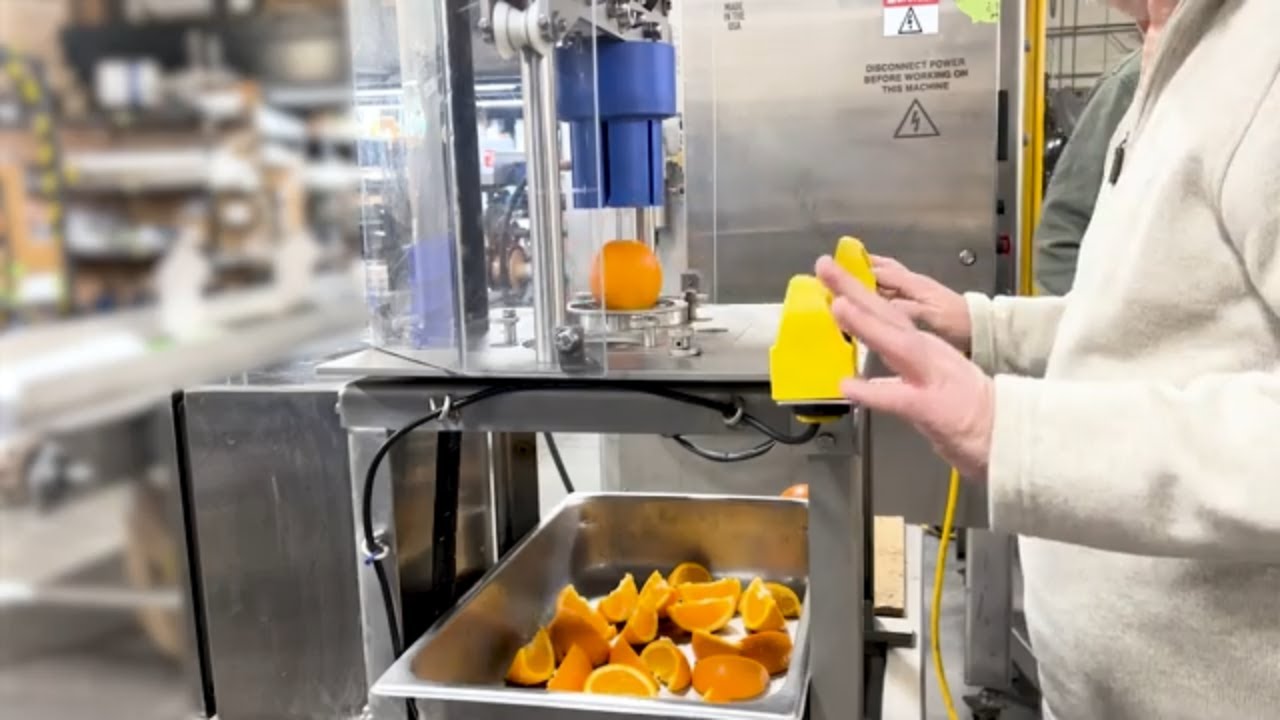

- Adjustable cutting assemblies for varied product sizes

- Stainless steel construction for sanitation and durability

- Clear safety guards and operator access points

- Consistent discharge systems that prevent product backup

- Easy disassembly for cleaning and maintenance

Prioritize machines that simplify daily tasks, maintain quality control, and meet the demands of continuous use. A well-matched cutting machine helps minimize downtime and supports long-term processing efficiency.

How Industrial Fruit Cutting Machines Improve Efficiency and Output

An industrial fruit and vegetable cutting machine helps maintain consistent output during peak hours. It reduces manual labor and lowers prep time while keeping cuts uniform across batches.

This kind of consistency keeps your kitchen running on schedule and limits waste from inconsistent sizing.

Having a dedicated industrial vegetable or fruit cutter supports steady production and helps your staff stay focused on final prep.